페이지 정보

본문

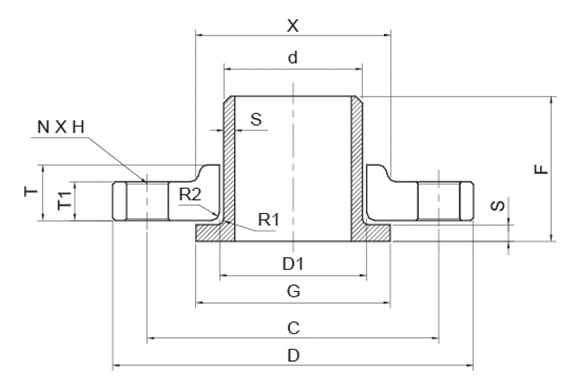

| Product | Composite Type Flanges |

|---|---|

| Category | Welding Neck |

| Name | [CW352H / A105 GAL'V As Per ASTM A153] ANSI 150LB & 300LB Composite Welding Neck Type Flange For Cu-Ni Pipe |

| Materials | CW352H / A105 GAL'V As Per ASTM A153 |

제품설명

- Unit : mm

| Pipe | Internal Flange | External Flange | Bolt | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N/D | O/D | d | G | S | F | G1 | D | C | D1 | T1 | T | X | R2 | N | H | |

| S10S | S40S | |||||||||||||||

| 1/2" | 21.3 | 21.3 | 35 | 2.11 | 2.77 | 52 | 3 | 90 | 60.3 | 22.9 | 11.2 | 16 | 30 | 3 | 4 | 15.9 |

| 3/4" | 26.7 | 26.7 | 43 | 2.11 | 2.87 | 51 | 3 | 100 | 69.9 | 28.2 | 12.7 | 16 | 38 | 3 | 4 | 15.9 |

| 1" | 33.4 | 33.4 | 51 | 2.77 | 3.38 | 51 | 3 | 110 | 79.4 | 34.9 | 14.3 | 17 | 49 | 3 | 4 | 15.9 |

| 1 1/2" | 48.3 | 48.3 | 73 | 2.77 | 3.68 | 51 | 6 | 125 | 98.4 | 50.0 | 17.5 | 22 | 65 | 6 | 4 | 15.9 |

| 2" | 60.3 | 60.3 | 92 | 2.77 | 3.91 | 64 | 8 | 150 | 120.7 | 62.5 | 19.1 | 25 | 78 | 8 | 4 | 19.1 |

| 3" | 88.9 | 88.9 | 127 | 3.05 | 5.49 | 64 | 10 | 190 | 152.4 | 91.4 | 23.9 | 30 | 108 | 10 | 4 | 19.1 |

| 4" | 114.3 | 114.3 | 157 | 3.05 | 6.02 | 76 | 11 | 230 | 190.5 | 116.8 | 23.9 | 33 | 136 | 11 | 8 | 19.1 |

| 6" | 168.3 | 168.3 | 216 | 3.40 | 7.11 | 89 | 13 | 280 | 241.3 | 171.4 | 25.4 | 40 | 192 | 13 | 8 | 22.3 |

| 8" | 219.1 | 219.1 | 270 | 3.76 | 8.18 | 102 | 13 | 345 | 298.5 | 222.2 | 28.6 | 44 | 246 | 13 | 8 | 22.3 |

| 10" | 273.0 | 273.0 | 324 | 4.19 | 9.27 | 127 | 13 | 405 | 362.0 | 277.4 | 30.2 | 49 | 305 | 13 | 12 | 25.4 |

| 12" | 323.9 | 323.9 | 381 | 4.57 | 9.52 | 152 | 13 | 485 | 431.8 | 328.2 | 31.8 | 56 | 365 | 13 | 12 | 25.4 |

| 14" | 355.6 | 355.6 | 413 | 4.78 | 9.52 | 152 | 13 | 535 | 476.3 | 360.2 | 35.0 | 79 | 400 | 13 | 12 | 28.6 |

| 16" | 406.4 | 406.4 | 470 | 4.78 | 9.52 | 152 | 13 | 595 | 539.8 | 411.2 | 36.6 | 87 | 457 | 13 | 16 | 28.6 |

| 18" | 457.0 | 457.0 | 533 | 4.78 | 9.52 | 152 | 13 | 653 | 577.9 | 462.3 | 39.7 | 97 | 505 | 13 | 16 | 31.8 |

| 20" | 508.0 | 508.0 | 584 | 5.54 | 9.52 | 152 | 13 | 700 | 635.0 | 514.4 | 42.9 | 103 | 559 | 13 | 20 | 31.8 |

| 24" | 610.0 | 610.0 | 692 | 6.35 | 9.52 | 152 | 13 | 815 | 749.3 | 616.0 | 47.7 | 111 | 663 | 13 | 20 | 35.0 |

- Unit : mm

| Pipe | Internal Flange | External Flange | Bolt | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| N/D | O/D | d | G | S | F | G1 | D | C | D1 | T1 | T | X | R2 | N | H | |

| S10S | S40S | |||||||||||||||

| 1/2" | 21.3 | 21.3 | 35 | 2.11 | 2.77 | 52 | 3 | 95 | 66.7 | 22.9 | 14.3 | 22 | 38 | 3 | 4 | 15.9 |

| 3/4" | 26.7 | 26.7 | 43 | 2.11 | 2.87 | 51 | 3 | 115 | 82.6 | 28.2 | 15.9 | 25 | 48 | 3 | 4 | 19.1 |

| 1" | 33.4 | 33.4 | 51 | 2.77 | 3.38 | 51 | 3 | 125 | 88.9 | 34.9 | 17.5 | 27 | 54 | 3 | 4 | 19.1 |

| 1 1/2" | 48.3 | 48.3 | 73 | 2.77 | 3.68 | 51 | 6 | 155 | 114.3 | 50.0 | 20.7 | 30 | 70 | 6 | 4 | 22.3 |

| 2" | 60.3 | 60.3 | 92 | 2.77 | 3.91 | 64 | 8 | 165 | 127.0 | 62.5 | 22.3 | 33 | 84 | 8 | 8 | 19.1 |

| 3" | 88.9 | 88.9 | 127 | 3.05 | 5.49 | 64 | 10 | 210 | 168.3 | 91.4 | 28.6 | 43 | 117 | 10 | 8 | 22.3 |

| 4" | 114.3 | 114.3 | 157 | 3.05 | 6.02 | 76 | 11 | 255 | 200.0 | 116.8 | 31.8 | 48 | 146 | 11 | 8 | 22.3 |

| 6" | 168.3 | 168.3 | 216 | 3.40 | 7.11 | 89 | 13 | 320 | 269.9 | 171.4 | 36.6 | 52 | 206 | 13 | 12 | 22.3 |

| 8" | 219.1 | 219.1 | 270 | 3.76 | 8.18 | 102 | 13 | 380 | 330.2 | 222.2 | 41.3 | 62 | 260 | 13 | 12 | 25.4 |

| 10" | 273.0 | 273.0 | 324 | 4.19 | 9.27 | 127 | 13 | 445 | 387.4 | 277.4 | 47.7 | 95 | 321 | 13 | 16 | 28.6 |

| 12" | 323.9 | 323.9 | 381 | 4.57 | 9.52 | 152 | 13 | 520 | 450.8 | 328.2 | 50.8 | 102 | 375 | 13 | 16 | 31.8 |

| 14" | 355.6 | 355.6 | 413 | 4.78 | 9.52 | 152 | 13 | 585 | 514.4 | 360.25 | 54.0 | 111 | 425 | 13 | 20 | 31.8 |

| 16" | 406.4 | 406.4 | 470 | 4.78 | 9.52 | 152 | 13 | 650 | 571.5 | 411.2 | 57.2 | 121 | 483 | 13 | 20 | 35.0 |

| 18" | 457.0 | 457.0 | 533 | 4.78 | 9.52 | 152 | 13 | 710 | 628.6 | 462.3 | 60.4 | 130 | 533 | 13 | 24 | 35.0 |

| 20" | 508.0 | 508.0 | 584 | 5.54 | 9.52 | 152 | 13 | 775 | 685.8 | 514.4 | 63.5 | 140 | 587 | 13 | 24 | 35.0 |

| 24" | 610.0 | 610.0 | 692 | 6.35 | 9.52 | 152 | 13 | 915 | 812.8 | 616.0 | 69.9 | 152 | 702 | 13 | 24 | 41.3 |

2. Process : Cold Forming

3. Heat Treatment : Annealing After Cold Forming

4. Temp & Hold Time : 750℃±50℃, 30Min / Inch(THK)